POLYKO EVA/PP/PE Film

-

Payment

L/C(sight) , T/T

-

MOQ

2 ea

-

Supply Ability

150 ea per Month

-

Supply Details

Customization Sample Order

(MOQ) / 2t, (MAX) 150t / month

-

Country of sale

World Wide, Americas, Asia, Europe, Middle East

-

PRICE

-

FOB

USD 3.00 ~ 6.00

(2 ea)

-

ITEM SPECIFICS

-

Brand

Model PK-MF-PE/PK-MF-PP/PK-MF-EVA, etcPOLYKO

-

origin

Republic of Korea

-

Size(Capacity)

Customizable

-

Function

For make pakage

-

Material

PE or PP or EVA

-

Color

Customizable in various thicknesses and widths. Features a unique dual-surface finish (one side glos

-

Dimensions

Depends on size

-

Weight

Depends on thickness and size

-

Style

Roll form

-

Expiry Date

Not applicable

-

Condition

New product

-

Features

Suitable for flexible packaging and printing applications

PRODUCT DESCRIPTION

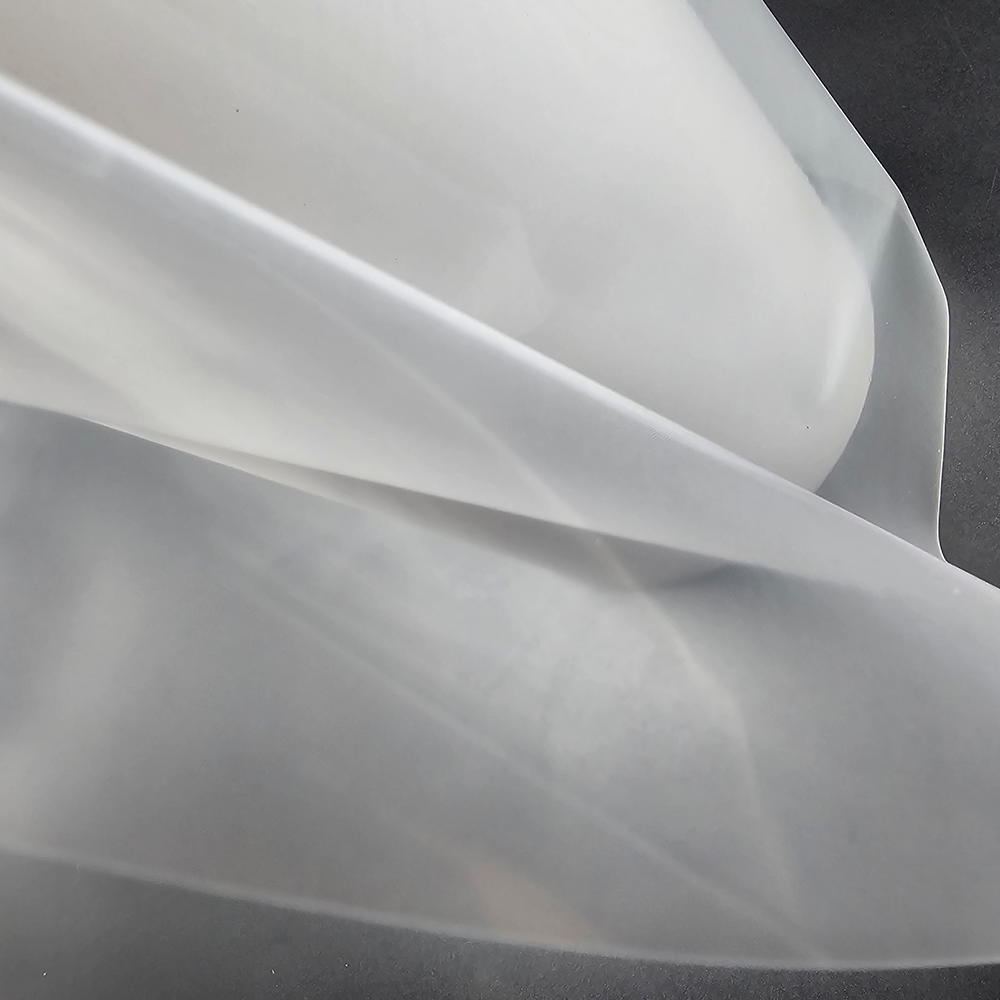

EVA/PP/PE Film

We manufacture high-quality films made from PE (Polyethylene), PP (Polypropylene), and EVA (Ethylene-Vinyl Acetate) using the casting process, which ensures consistent thickness and superior physical properties.

Depending on customer requirements, we can produce everything from single-material films to triple-x-layer films, delivering optimized solutions in terms of clarity, durability, barrier performance, and tactile quality.

Depending on customer requirements, we can produce everything from single-material films to triple-x-layer films, delivering optimized solutions in terms of clarity, durability, barrier performance, and tactile quality.

PE film is soft, flexible, and maintains its strength even at low temperatures, making it ideal for refrigerated and frozen packaging.

PP film offers high rigidity and heat resistance, making it suitable for microwave defrosting and high-temperature sterilization, with excellent moisture barrier properties.

EVA film provides superior elasticity, impact resistance, and transparency, and is highly processable for premium packaging applications.

In particular, we have developed a technology to modify the surface of EVA film to create a silk-like soft texture with a subtle sheen.

This surface treatment adjusts the microstructure to offer a luxurious feel, making it ideal for apparel, fashion, and premium food packaging.

We also produce functional films by incorporating naturally derived minerals into the raw material, which help preserve freshness by reducing oxygen and moisture transmission while maintaining the original taste and aroma of food.

Additionally, our anti-fog film technology prevents condensation in refrigerated and frozen environments, keeping packaged goods visible and appealing — especially useful for fresh produce, salads, fruits, and vegetables.

Through eco-friendly single-material design and customization, we enhance both recyclability and product competitiveness.

With a commitment to quality and sustainability, we deliver film solutions optimized for global food, apparel, and industrial packaging markets.

Features

Customizable in various thicknesses and widths. Features a unique dual-surface finish (one side glossy, one side matte). Excellent adhesion and flexibility, suitable for a wide range of packaging materials.

Company Overview

POLYKO Inc. is a leading Korean manufacturer of plastic packaging materials, specializing in PE, PP, and EVA film extrusion, zipper production, and zipper bag converting. With over 20 years of experience, we offer one-stop packaging solutions for apparel, food, baby products, and industrial use.

Our factory is equipped with advanced extrusion and converting lines, ensuring stable quality and fast delivery. We support OEM/ODM orders, small MOQs, and eco-friendly materials.

POLYKO is committed to quality, flexibility, and long-term partnerships with global clients.

Our factory is equipped with advanced extrusion and converting lines, ensuring stable quality and fast delivery. We support OEM/ODM orders, small MOQs, and eco-friendly materials.

POLYKO is committed to quality, flexibility, and long-term partnerships with global clients.

Other Products

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Telegraphic Transfer : T/T

- Name : Yang Ki Jin

SHIPPING

Shipping from :

Republic of Korea

- 16 Gahyeon-ro Tongjin-eup, Gimpo-si, Gyeonggi-do (10038)

Polyko Inc.

The person in charge

Tae yong YangAddress

16 Gahyeon-ro Tongjin-eup, Gimpo-si, Gyeonggi-do (10038)

큐알

Polyko Inc.

Introduction

POLYKO Inc. is a leading Korean manufacturer of plastic packaging materials, specializing in PE, PP, and EVA film extrusion, zipper production, and zipper bag converting. With over 20 years of experience, we offer one-stop packaging solutions for apparel, food, baby products, and industrial use. Our factory is equipped with advanced extrusion and converting lines, ensuring stable quality and fast delivery. We support OEM/ODM orders, small MOQs, and eco-friendly materials. POLYKO is committed to quality, flexibility, and long-term partnerships with global clients.

-

- Business Type :

- Manufacturer

-

- Main Product :

- PE,PP,EVA Film(transparent,Matt,etc), Slide Zipper, Single line Zipper, Slide Zipper Bag, etc

-

- Established :

- 2000-03-01

-

- Total Annual Revenue :

- 3~5 million (KRW)

-

- Total Employees :

- Less than 5

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- 3~5 million (KRW)

-

- Total export revenue (previous year in USD)

-

- Number of foreign trade employees

- Less than 5

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

- MEMBER

- Polyko Inc. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★